Unfortunately, having had to work over part of the weekend, I am not quite as far along as I'd hoped. Still, one major job has been done - CV boots.

The design is quite clever - basically a FWD type driveshaft, running up the middle of the axle tube to the differential. It doesn't need an inner CV joint because the splined end of the shaft slots into the diff (like on the back end of a live-axle car such as an MGB or TR7).

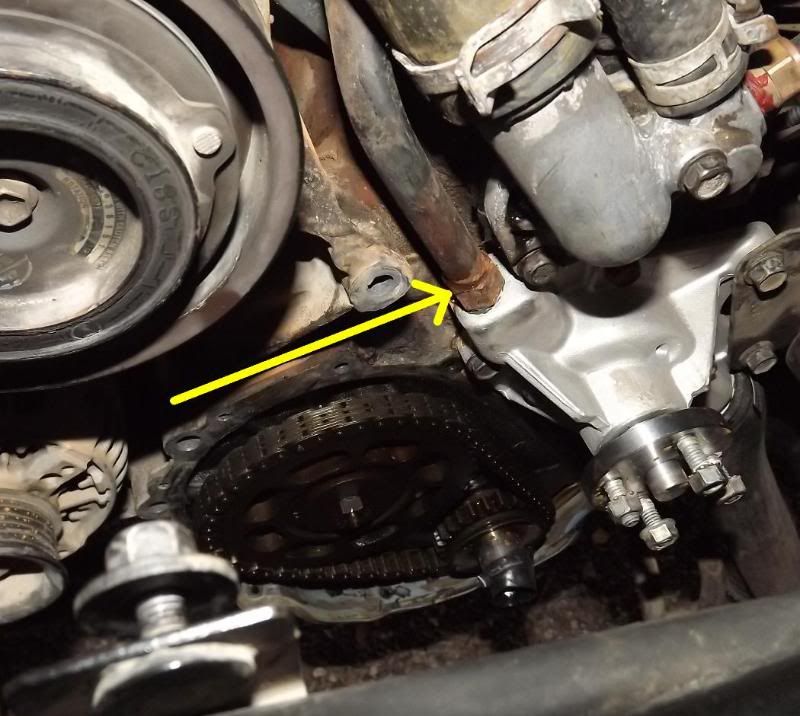

The offending items looked like this. You can see that the torn one was full of dirt which I washed out using carb cleaner before regreasing.:

Doing the job is much like the front of a FWD car - brakes off is step one. However, the Jeep axle has a clever design that allows the brake caliper AND disc to be removed without having to remove the caliper carrier:

The workshop manual talks about dismantling the front hub and bearings, balljoints and so on and I did some of that before realising that there was an easier way. The hub is held in with 3 bolts and if you remove them you can slide out the hub, brake dustshield, CV joint and half-shaft as one unit.

Then the old boot can be removed, grease cleaned out, new grease pushed in and a new boot fitted.

I then found that the boot-securing band fouled the axle, so it had to be removed and a heavy duty cable tie was fitted AFTER the shaft was back in.

The missing ARB droplink bolt was replaced, along with new bushes (they need to be removed, though, to fit a couple of washers). Steering and front end control are dramatically improved!

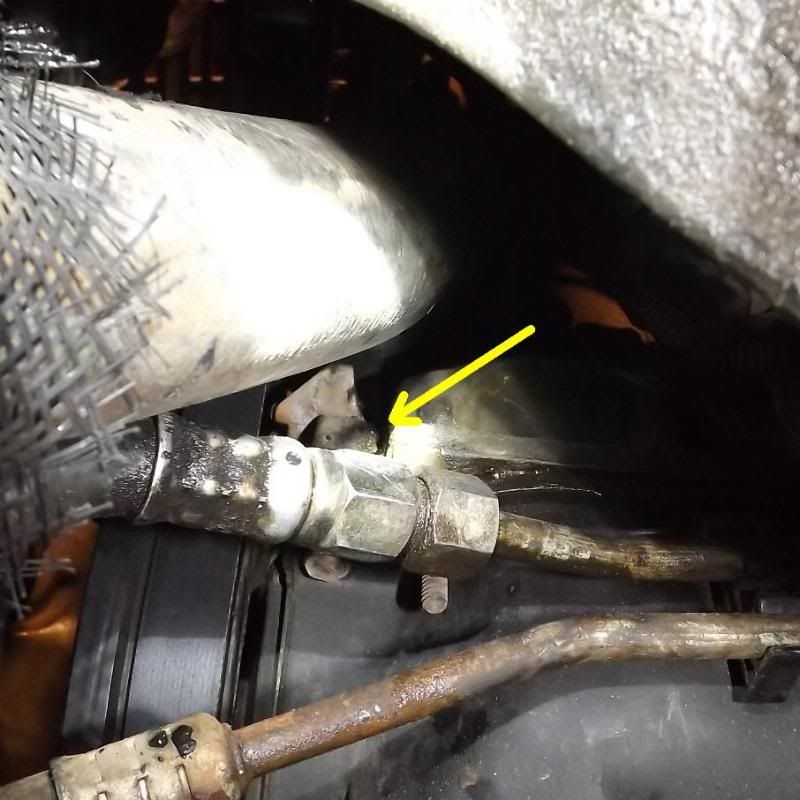

There was a grease nipple under all this - so that was cleaned up and the joint regreased, along with about 5 or 6 others

Just about ready for the roadworthiness test now.